In 2026, the global tissue market stands at a turning point. Growth is no longer driven by simple price competition—it's powered by a fundamental shift where haptics (the science of touch) and visual aesthetics have become the primary drivers of brand loyalty.

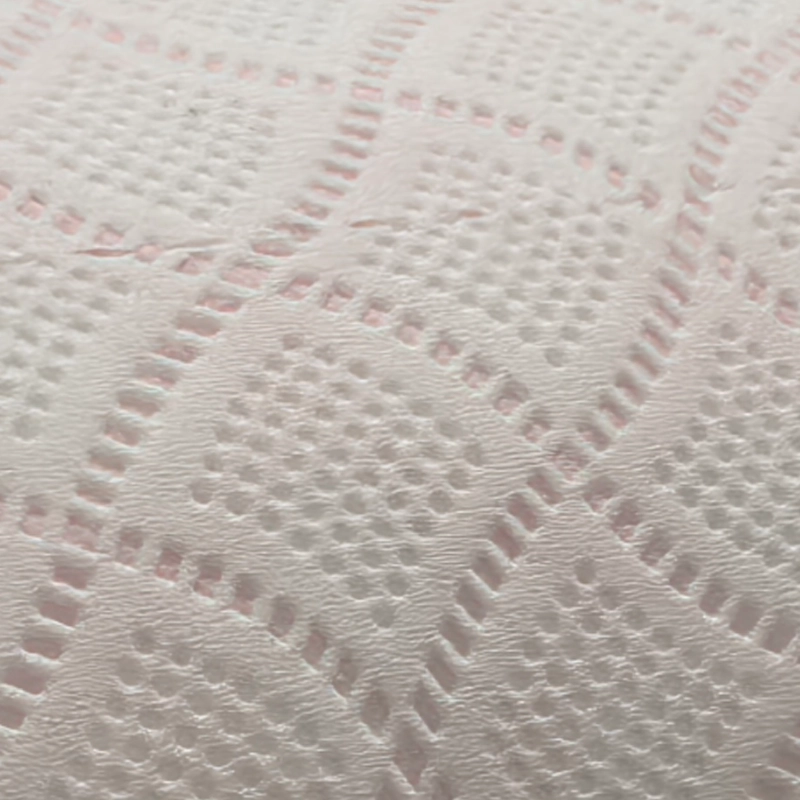

For tissue manufacturers, embossing is no longer just a decorative process—it's the engineering bridge between commodity paper and high-value branded products.

One of the strongest trends is the demand for "voluminous" rolls that use less fiber. Technology like Point-to-Point (PTP) and next-gen Hot Embossing are solving this by creating maximum air pockets between plies.

Point-to-Point

Point-to-Point

Nested Geometry

Nested Geometry

Deco Relief

Deco Relief

Plain white tissue is losing ground to high-definition patterns. Categories surging in popularity include:

"Haptic Tech" isn't just a buzzword. It's the engineering of liquid management systems.

Modern kitchen towel embossing employs Deep Pillow Zones for retention and tight Channel Systems for scrubbing power. Research shows these micro-embossing processes directly enhance Klemm capillary rise properties.

Pattern Psychology: Using embossing patterns that mimic natural textures enables brands to communicate the use of alternative fibers without words.

Bamboo leaf textures and linen-effects suggest durability and renewable resources, resonating with Gen-Z and eco-conscious buyers.

The tissue embossing landscape of 2026 rewards manufacturers who view pattern technology as a strategic brand-building tool. At Tongbang Intelligent Equipment, our Non-Stop and Start-Stop series are engineered to handle the 70+ HRC rollers and precision tension control needed for these premium textures.

The future of tissue is textured, premium, and sustainable. Is your technology ready?