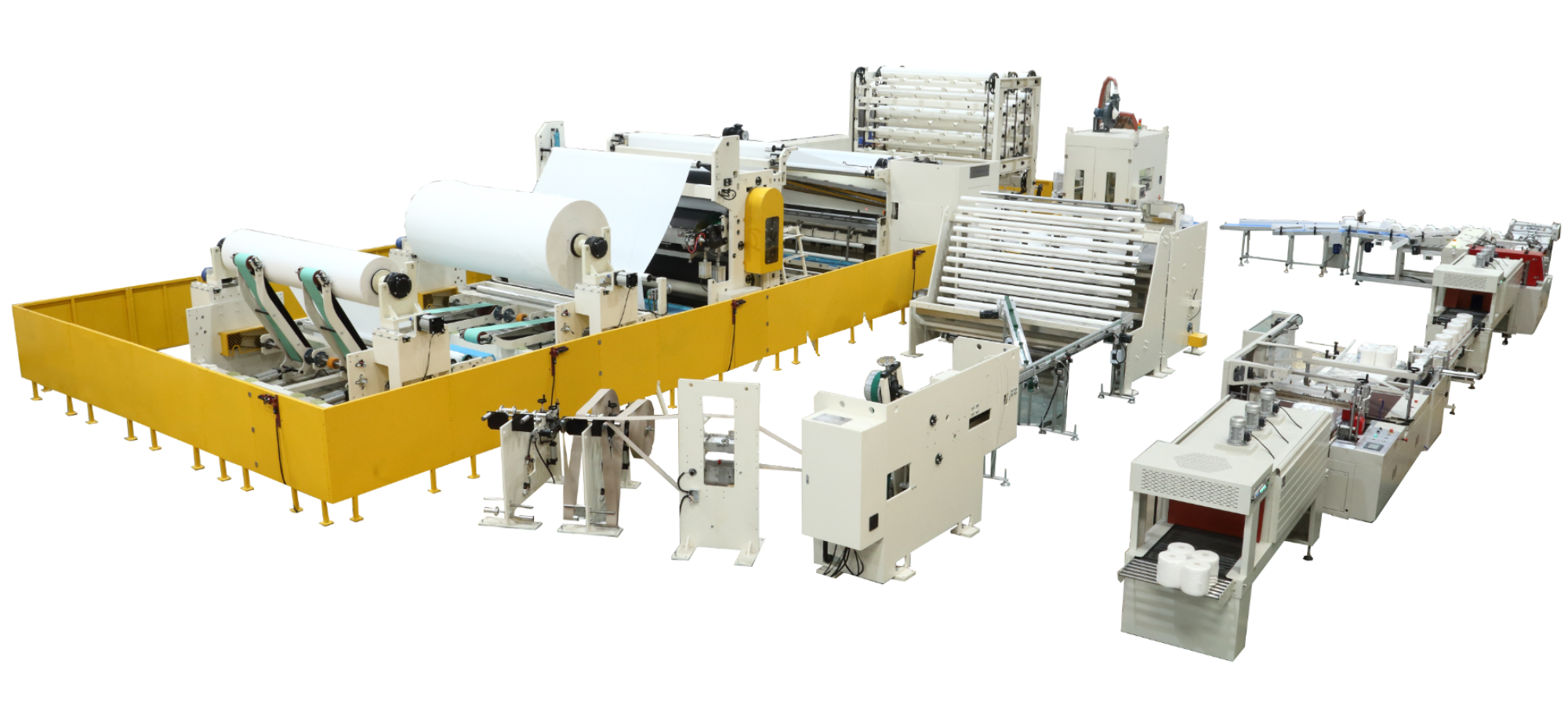

| Design Speed | 350 m/min |

| Production Speed | 300 m/min (Stable) |

| Paper Grammage | 14 - 35 g/m² (Versatile Range) |

| Rewinding Type | Non-Stop (Surface Winding) |

| Log Output | 33 - 38 Logs/min (Synchronized) |

| PLC & CPU | Siemens S7 Series (Germany) |

| Servo System | Siemens Motion Control (Germany) |

| Control System | Schneider Electric (France) |

| Steel Roll Diameter | Φ494 mm (Oversized for Stability) |

| Surface Hardness | 70 HRC (Alloy Coated for Durability) |

| Embossing Type | Steel To Rubber / Steel To Steel (Customizable) |

| Lamination Unit | Point-to-Point / DES / Nested (Optional) |

| Technology | Vibration-Free High Speed Design |

| Load Capacity | 3,000 kg (Heavy Duty Structure) |

| Parent Roll Width | Max. 2900 mm |

| Parent Roll Dia. | Max. Φ2500 mm |

| Driving Mode | Independent Motor Drive (Siemens Inverter) |

| Tension Control | Pneumatic & Encoder Feedback Loop |

| Web Cutting | Rear Doctor Blade System |

Technical experts ready to respond within 24 business hours

We prioritize reliability and ease of maintenance. By using a “German/French Heart” (Siemens PLC/Servos and Schneider Relays), we ensure that our clients in Latin America and globally can easily find spare parts and technical support locally, minimizing downtime compared to obscure brands.

The oversized Φ494 mm steel roll provides superior stability compared to standard smaller rolls. Its larger mass dissipates heat better and significantly reduces vibration at high speeds (300 m/min), resulting in a consistent, high-quality embossing pattern on the finished product.

Absolutely. The TB-JRT300 is designed with a reinforced Unwind Stand capable of loading Parent Rolls up to 3,000 kg and 2500 mm in diameter. This allows for longer production runs with fewer roll changes, maximizing efficiency.

The machine is synchronized to produce between 33 to 38 logs per minute, depending on the perforation pitch and roll length. The Log Saw is fully integrated to match this speed without bottlenecks.