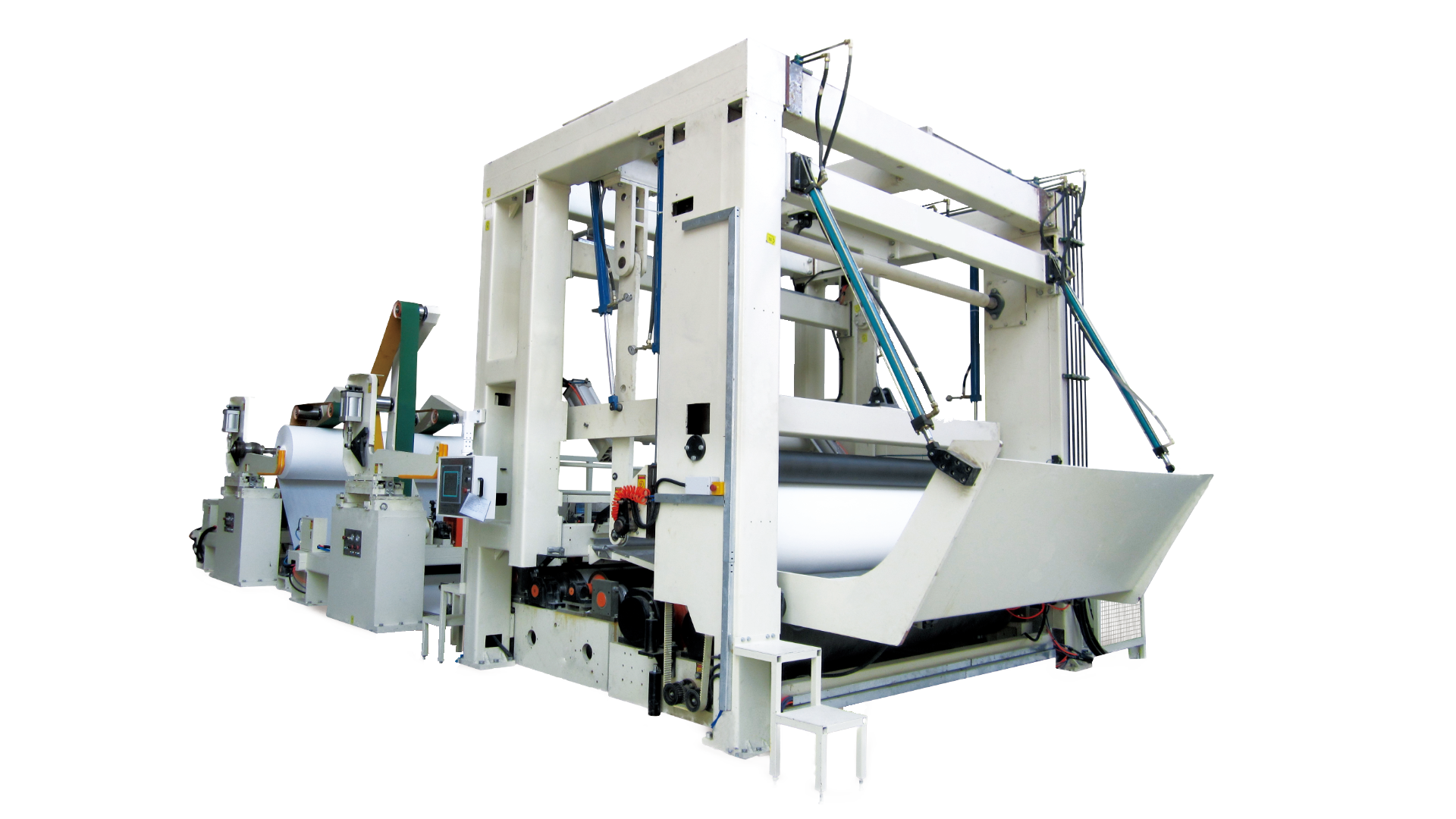

Engineered for perfect edge quality and distinct roll separation at 1500 m/min.

Minimizing downtime with smart automation and heavy-duty components for non-stop converting.

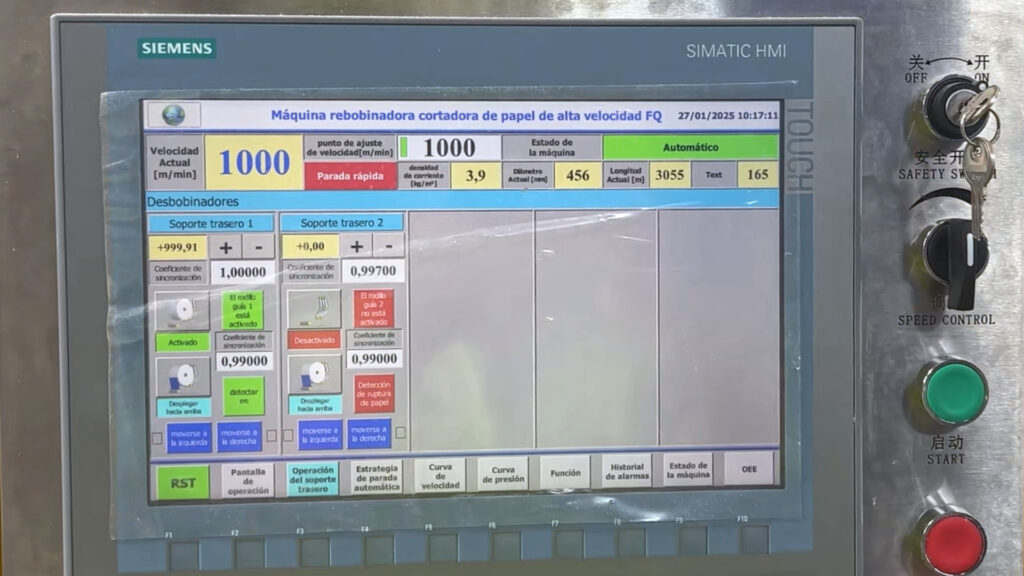

Siemens S7 PLC with closed-loop load cell feedback for constant web tension.

Flexible cutting modules adaptable to tissue grades and GSM requirements.

Optional automated knife setup for rapid format changes (< 2 mins).

Perfect density and structure for downstream converting efficiency.

High-performance specifications for the FQA1500 model.

| Machine Model | TB-FQA1500 (FQ High Speed Series) |

| Design Speed | 1500 m/min |

| Width of Jumbo Roll | 2950 mm / 3550 mm / 3950 mm / 4250 mm |

| Dia. of Finished Roll | ≤ Φ1500 mm (Others to order) |

| Dia. of Jumbo Roll | Φ 2000 / 2500 / 3000 mm |

| Slitting Width | Min 80mm - Max to Jumbo roll width |

| Rewinding System | Pneumatic synchronous winding (Surface Rewinding) |

| Slitting System | Imported slitting knives |

| Automation | Auto roll change + Hydraulic discharge |

| Control System | Siemens Motion Control System |

| Unwinder | 1-4 Backstands (Customizable) |

| Motive Power | Approx. 120KW (Individual Inverter Control) |

| Optional Units |

Calendering: Steel to Steel / Steel to Rubber Lamination: Point to Point / Decorative Embossing Lotion: Double-side cream application device |

Features a native SIEMENS Simatic touch panel with real-time diagnostics. Operators can manage tension recipes, visualize speed curves (up to 1000+ m/min), and control individual servo drives with zero latency.

Equipped with heavy-duty pneumatic knife holders for vibration-free cutting. The tangential shear system ensures dust-free edges even on high-GSM Kraft paper, with rapid positioning setup.

Engineered to handle jumbo parent rolls up to 2500mm diameter. The shaftless floor pick-up system and hydraulic unloading arms streamline the workflow, minimizing downtime between roll changes.

Get a Technical Proposal & Layout within 24h.