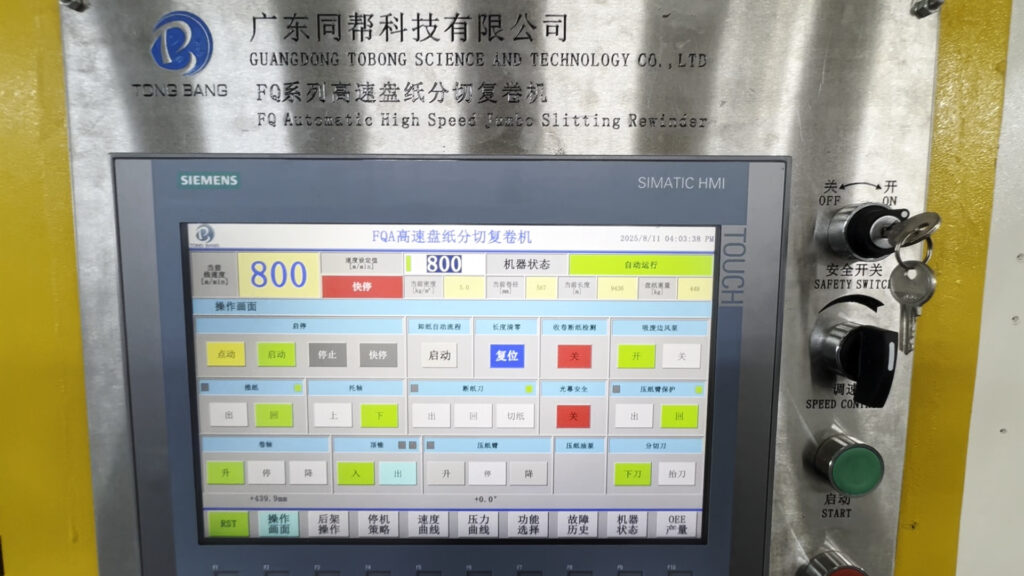

Engineered for intelligent control. Combining robust mechanical stability with advanced Siemens logic for perfect tension management at 800 m/min.

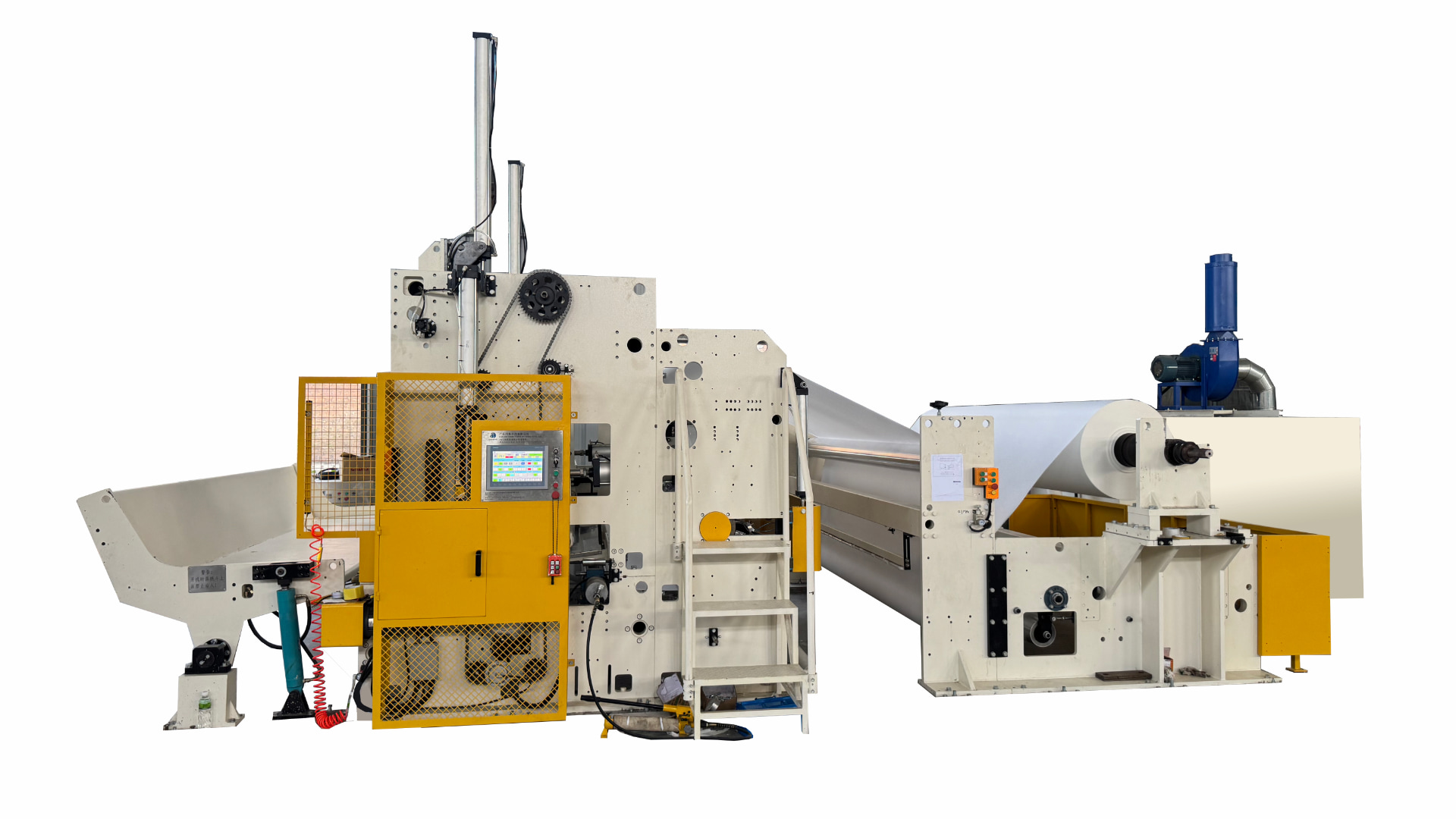

Minimizing downtime with smart automation and heavy-duty components for non-stop converting.

Siemens S7 PLC with closed-loop load cell feedback for constant web tension.

Flexible cutting modules adaptable to tissue grades and GSM requirements.

Optional automated knife setup for rapid format changes (< 2 mins).

Perfect density and structure for downstream converting efficiency.

Reliable precision slitting for MG and Interleaving papers.

| Machine Model | TB-MG800 (MG Paper Series) |

| Application Material | MG Paper, Interleaving Paper, Wrapping Paper (14-120 gsm) |

| Working Speed | 800 m/min |

| Working Width | 2850 mm (Standard) |

| Dia. of Finished Roll | ≤ Φ1200 mm |

| Dia. of Jumbo Roll | Φ 2000 mm / 2500 mm |

| Tension Control | Automatic Closed-Loop Tension |

| Slitting System | Shear Knife / Razor Blade (Configurable) |

| Rewinding System | Center-Surface Rewinding |

| Control System | Siemens PLC + Servo Drive |

| Unwinder | Shaftless Unwind Stand (Hydraulic Lift) |

| Optional Units |

Auto-Splicing: Automatic paper splicing unit Handling: Automatic finished roll pusher Trim: Vacuum suction system |

The brain of the MG-800. A native SIEMENS Simatic HMI offers real-time visualization of speed, diameter, and tension. The system allows for ‘One-Touch’ recipe recall, minimizing setup time for different paper grades.

Reliability is in the details. Our electrical cabinets feature immaculate wiring standards and top-tier components (Siemens/Schneider). This organized architecture ensures interference-free signal transmission and simplifies future diagnostics.

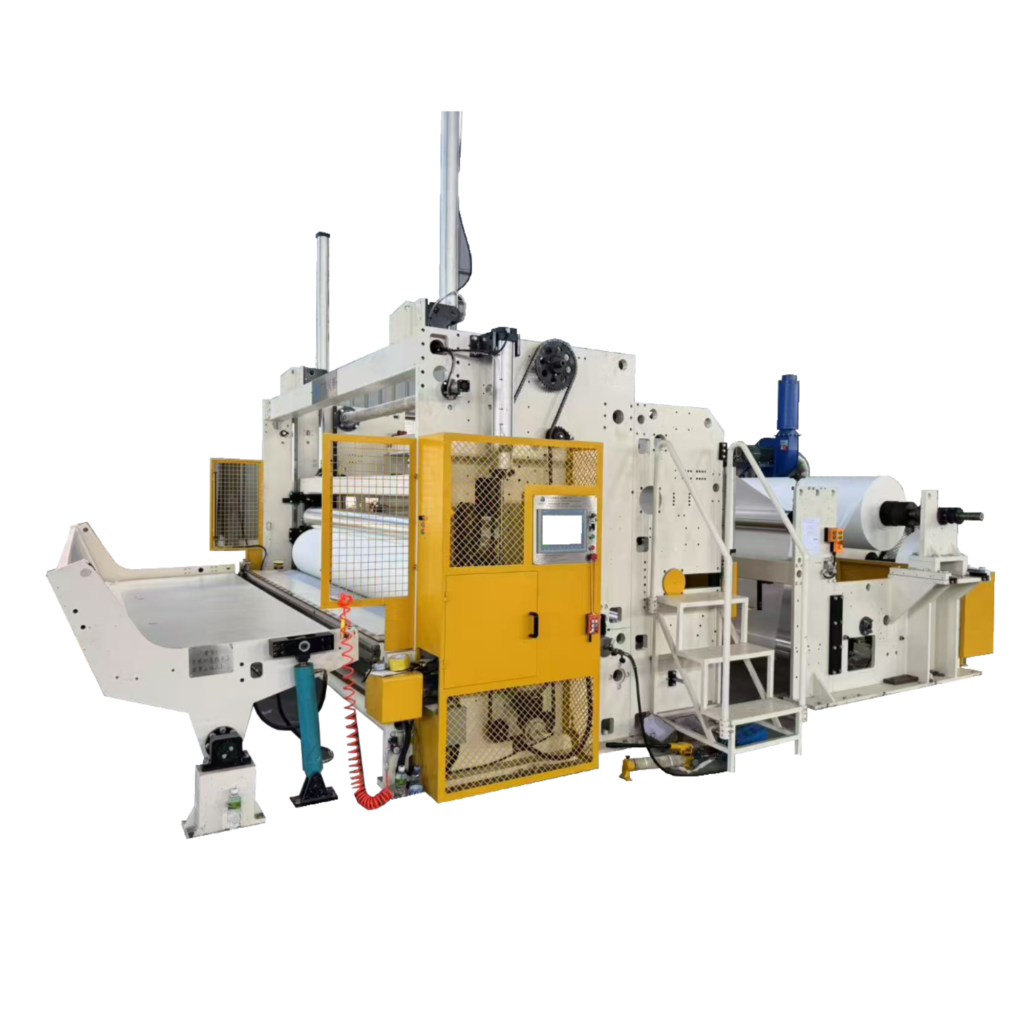

Built on a vibration-dampened steel chassis encased in industrial safety guarding. The layout provides easy access for maintenance while ensuring operator safety during high-speed operation (800 m/min).

Get a Technical Proposal & Layout within 24h.