Fully automatic start-stop rewinder designed for high-efficiency toilet tissue and kitchen towel production. Engineered for reliability and ease of operation.

| Machine Model | TB-FJC300 |

| Working Speed | 300 m/min (High-Speed Stable) |

| Finished Roll Diameter | Φ 100 - 300 mm (Tightness Adjustable) |

| Core Capability | Core & Coreless Production (Automatic Switching) |

| Finished Roll Core | Φ 50 - 80 mm |

| Perforation Pitch | 120 mm (Customizable / Servo Controlled) |

| Automation Functions | Auto Core Feeding, Web Cutting, And Blowing |

| Log Output | 18 - 25 Logs/min (Depending on sheets) |

| Jumbo Roll Width | 2750 mm - 3550 mm (Model Dependent) |

| Jumbo Roll Diameter | Up to Φ 2500 mm |

| Unwind Stand | 1 - 4 Ply (Independent Tension Control) |

| Programmable Controller | Siemens S7 Series PLC (Germany) |

| Motive Power | 37.5 KW (Individual Inverter Regulation) |

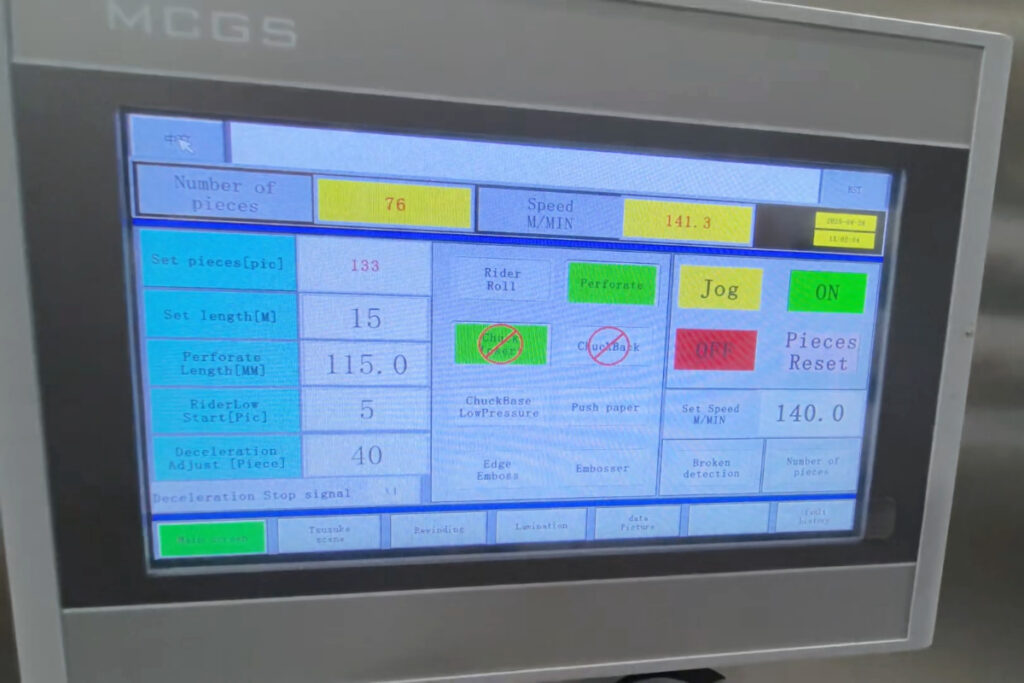

| HMI Interface | Smart Touch Screen (Multi-Language Support) |

| Pneumatic System | 3HP Air Compressor / 5kg/cm² Min. Pressure |

| Jumbo Roll Core | Φ 76.2 mm (Standard 3") |

| Embossing Device | Steel to Rubber / Steel to Paper (Single or Double) |

| Glue Laminator | Point-to-Point / Decorative Embossing |

| Edge Embossing | Airbag Pressurization Unit (Side Line/Pattern) |

| Slitter Device | Specialized for Hand Towel Paper Conversion |

| Printing Unit | 1 - 2 Color Printing System (Optional) |

| Downstream Sync | Auto Unload & Connection to Log Saw Line |

| Safety Features | Emergency Stop Sensors & Safety Guarding |

Technical experts ready to respond within 24 business hours

We equip the TB-FJC300 with a cutting-edge HMI interface that allows for total real-time production monitoring. From this panel, operators manage the stable 300 m/min working speed, precise perforation counts, and automatic synchronization, ensuring a smooth operation with minimal human intervention.

Mechanical robustness is the key to stability. This section showcases our reinforced steel roller system and precision guides that ensure a consistent, vibration-free paper flow. This industrial design prevents web breaks even with low GSM stock, maintaining perfect tension throughout the entire rewinding process.

Our high-definition embossing technology delivers a finished product with superior bulk and exceptional softness. As seen in the relief detail, our precision rollers guarantee sharp, uniform patterns, elevating your brand quality to successfully compete in the premium tissue market.

Standard Start-Stop machines typically run at 180-200 m/min. The TB-FJC300 is engineered with reinforced structures and an advanced Frequency Conversion Speed Regulator, allowing it to reach design speeds of 300 m/min, significantly boosting your daily output compared to entry-level models.

Yes. It is fully equipped with an Embossing and Lamination Unit, allowing you to produce fluffy, high-quality kitchen towels. The machine handles the thicker grammage of kitchen towel paper efficiently.

Absolutely. The machine is versatile and can be configured to produce rolls with or without cores. The tightness of the winding is adjustable to ensure solid coreless rolls maintain their shape.

We use industry-standard Mitsubishi or Siemens PLCs (customizable upon request) to ensure stable logic control and easy troubleshooting for local technicians.