Ultra-high speed start-stop rewinder engineered for industrial-scale toilet tissue and kitchen towel production. Delivering an industry-leading 400 m/min for maximum output, reliability, and precision.

| Machine Model | TB-FJC400 (Series 2800 / 3000 / 3600) |

| Production Speed | 400 m/min (Ultra-High Speed Stable) |

| Finished Roll Diameter | Φ 100 - 300 mm (Precision Control) |

| Rewind Type | Automatic Start-Stop Line |

| Finished Roll Core | Φ 50 - 80 mm |

| Perforation Pitch | 120 mm (Standard) / Servo-Adjustable |

| Output Capacity | Up to 35 Logs/min (Industrial Volume) |

| HMI Interface | 10" Touch Screen (User Friendly) |

| Motive Power | 75 KW (Individual Inverter System) |

| Jumbo Roll Width | 2750 mm - 3550 mm |

| Jumbo Roll Diameter | Φ 1500, Φ 2000, Φ 2500 mm |

| Jumbo Core Inner Dia | Φ 76.2 mm (Standard) |

| Unwind Stands | 1 - 4 Ply (Customizable Configuration) |

| Controller System | High-Performance PLC Computer Programming |

| Pneumatic Control | 3HP System / 5kg/cm² Working Pressure |

| Power Supply | 380V 50HZ (Standard Industrial) |

| Embossing System | Single/Double (Steel to Rubber / Steel to Paper) |

| Glue Lamination | Point-to-Point / Decorative Glue Unit |

| Edge Embossing | Independent Side Line / Pattern Unit |

| Slitter Unit | Specialized for Hand Towel Paper Conversion |

| Log Saw Sync | Full Automation Integration Available |

Technical experts ready to respond within 24 business hours

At the heart of the TB-FJC400 are reinforced steel rollers designed for maximum structural integrity. This heavy-duty system ensures constant web tension and perfect paper alignment even at its top speed of 400 m/min. Engineered to resist vibration, these rollers guarantee long-term reliability and high-precision winding for industrial-scale operations.

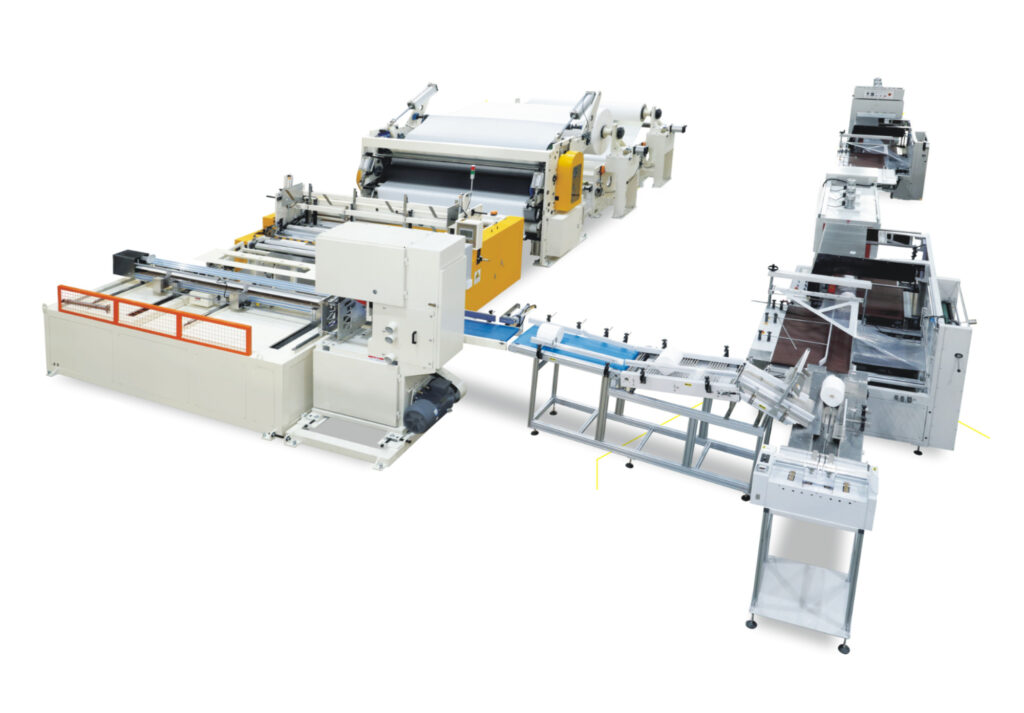

Our full-scale start-stop rewinder line is a powerhouse of efficiency. This panoramic view shows a complete factory integration, combining core feeding, high-speed winding, and automated web cutting into one seamless workflow. The TB-FJC400 is built for heavy-duty environments, allowing for stable, continuous production with minimal manual intervention.

The excellence of our engineering is reflected in the final product. The TB-FJC400 produces toilet tissue rolls with uniform winding density and exceptional bulk. Our advanced tension control technology ensures a premium finish and perfect softness, providing your brand with a high-quality product that meets the most demanding market standards.

The TB-FJC400 is built on a Heavy-Duty Frame. This reinforced structure allows it to handle higher acceleration and deceleration forces without vibration, providing a faster cycle time and higher daily output than standard Start-Stop models.

Yes. The TB-FJC400 is fully compatible with our Precision Glue Lamination Unit. This allows you to produce 2-ply or 3-ply kitchen towels with high bonding strength and bulk, similar to premium non-stop lines.

We utilize an advanced Frequency Conversion Control combined with a high-response braking system. This smooths out the stop-and-go curve, protecting the motors and reducing mechanical wear even when running near design speeds.

Absolutely. The machine features an Automatic Log Ejection system that can feed directly into an Accumulator and then to an Orbit-Saw or Band-Saw, creating a fully automatic conversion line.