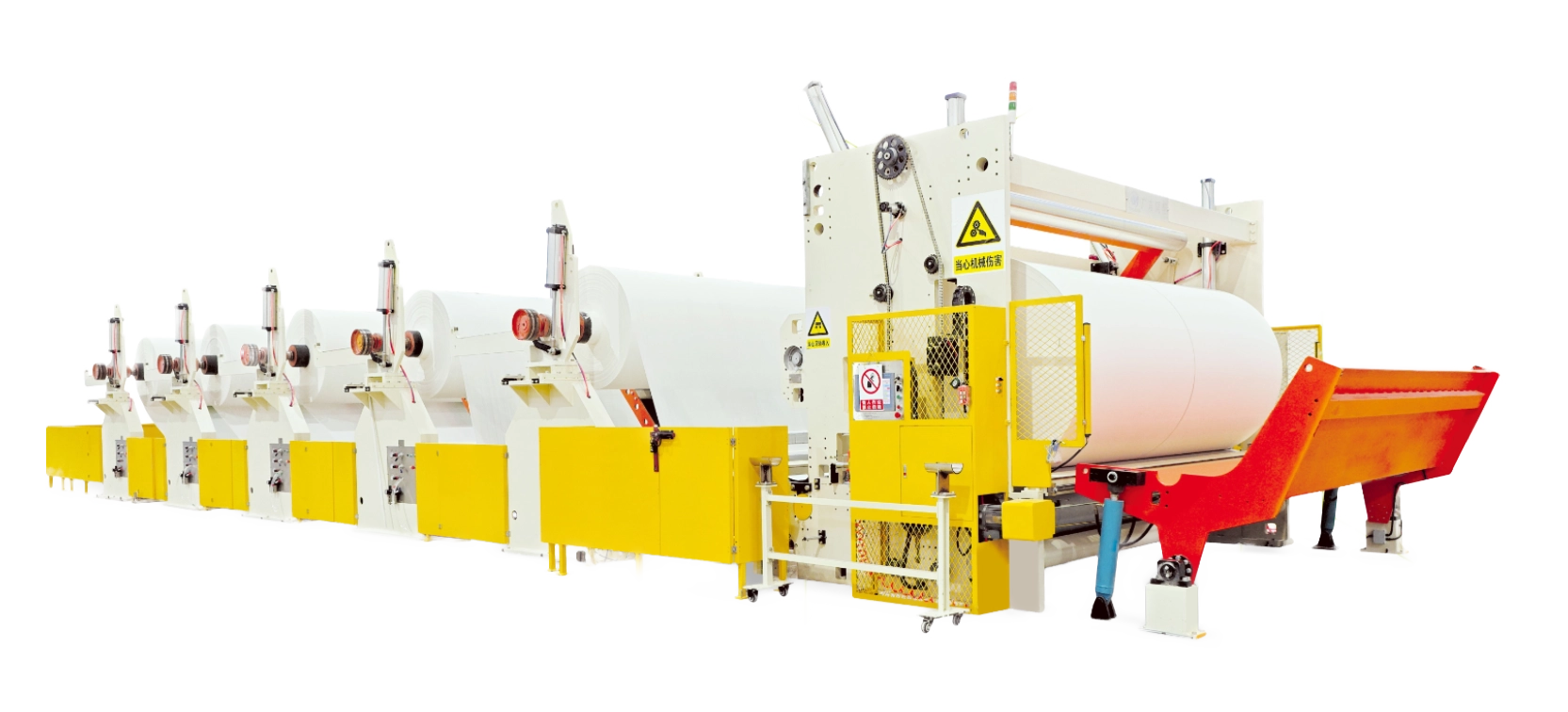

The industry standard for reliability. Engineered for vibration-free stability and precision winding at 1300 m/min.

Minimizing downtime with smart automation and heavy-duty components for non-stop converting.

| Machine Model | TB-FQA1300 (FQ High Speed Series) |

| Width of Jumbo Roll | Max. 1300 mm |

| Working Speed | 500 - 600 m/min (Customizable up to 800) |

| Dia. of Finished Roll | ≤ Φ1200 mm (Standard) / Other size to order |

| Dia. of Jumbo Roll | Φ 1500 mm (Standard) |

| Slitting Width | Min 80mm - Max to Jumbo roll width |

| Rewinding System | Pneumatic synchronous winding |

| Slitting System | Imported slitting knives (Shear/Razor) |

| Roll Discharger | Auto change roll + Hydraulic discharge |

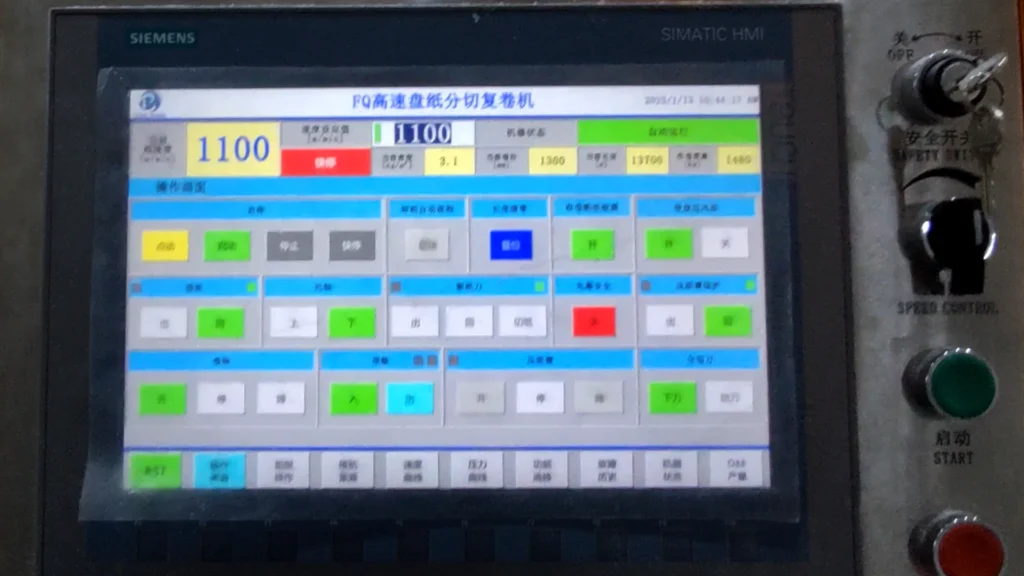

| Programmable Controller | Motion Control System (Siemens) |

| Stop Mode | By diameter or length |

| Unwinder | 1-2 Stands (Customized) |

| Motive Power | Individual inverter to regulate speed |

| Optional Configurations |

Calendering Unit: Steel to steel roller Lamination: Point to point, decorative embossing Cream Device: Cream on the double-side |

Features a native SIEMENS Simatic touch panel with real-time diagnostics and tension visualization. The user-centric interface allows operators to manage recipe presets, monitor speed curves, and synchronize the entire line with zero-latency servo precision.

Equipped with heavy-duty pneumatic knife holders for vibration-free stability. The tangential shear system ensures dust-free edges even on high-GSM Kraft paper or delicate tissue, while the integrated bowed roller guarantees perfect web separation before rewinding.

Engineered for heavy workloads. The floor pick-up system uses powerful hydraulic arms to lift Jumbo Rolls up to 1500mm diameter directly from the floor, eliminating the need for overhead cranes and reducing changeover time by 40%.

Get a Technical Proposal & Layout within 24h.