Optimized for maximum ROI and stable, long-run production at 800 m/min.

Minimizing downtime with smart automation and heavy-duty components for non-stop converting.

Balanced performance for mid-to-high volume production.

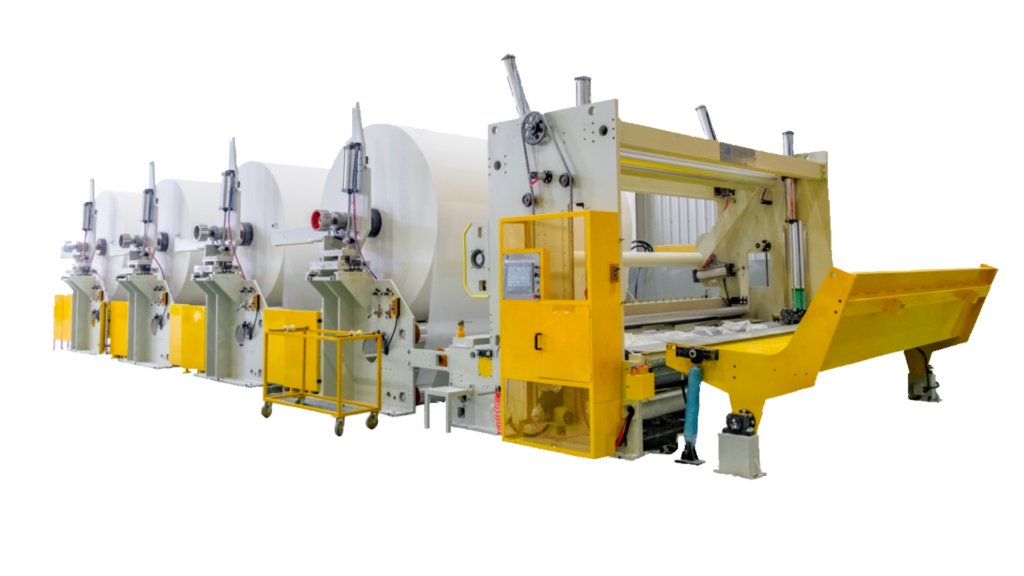

| Machine Model | TB-FQB800 (FQ High Speed Series) |

| Working Speed | 800 m/min |

| Width of Jumbo Roll | 2950 mm / 3550 mm |

| Dia. of Finished Roll | ≤ Φ1500 mm (Standard) |

| Dia. of Jumbo Roll | Φ 2000 / 2500 / 3000 mm |

| Slitting Width | Min 80mm - Max to Jumbo roll width |

| Rewinding System | Pneumatic synchronous winding |

| Slitting System | Imported slitting knives (Shear/Razor) |

| Discharge System | Auto roll change + Hydraulic discharge |

| Control System | Siemens Motion Control System |

| Unwinder | 1-3 Backstands (Customizable) |

| Motive Power | Individual Inverter Control (Variable) |

| Optional Units |

Calendering: Steel to Steel / Steel to Rubber Lamination: Point to point, decorative embossing Specialty: Double-side cream application |

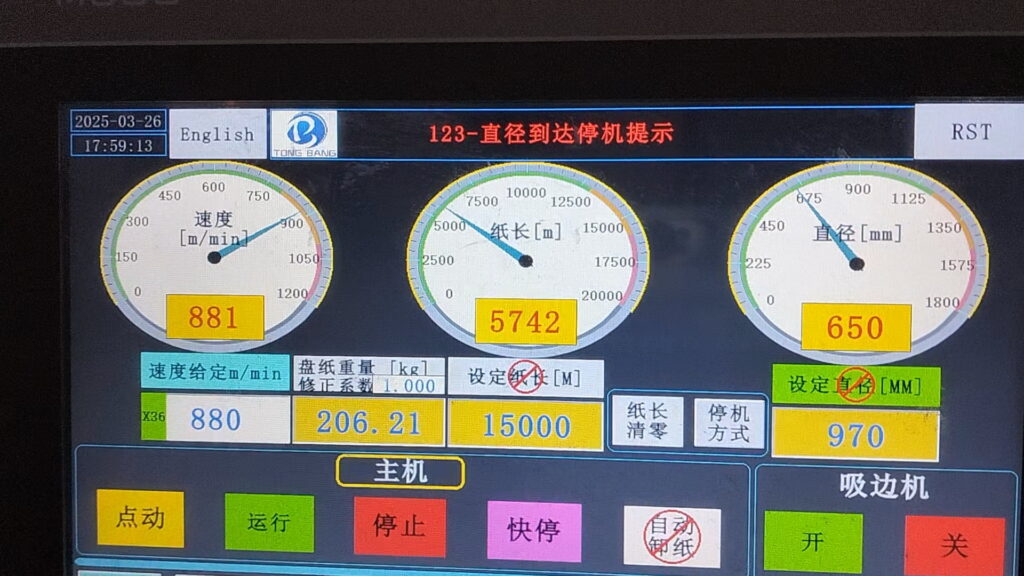

Operators gain full control with our intuitive dashboard. As shown in the live data, the S-800 maintains rock-solid stability even when pushing beyond its rated limit (running here at 881 m/min). The analog-style gauges provide instant visual feedback on speed, linear length, and roll diameter.

Engineered with a rigid steel portal frame that guarantees zero vibration at 800 m/min. The synchronized rider roll system ensures uniform density across the entire web width, delivering perfectly straight-edged rolls every cycle.

Maximize your shipping efficiency. The S-800 handles finished roll diameters up to 1200mm. The integrated discharge system smoothly transfers heavy rolls to the conveyor, ready for immediate wrapping and dispatch.

Get a Technical Proposal & Layout within 24h.