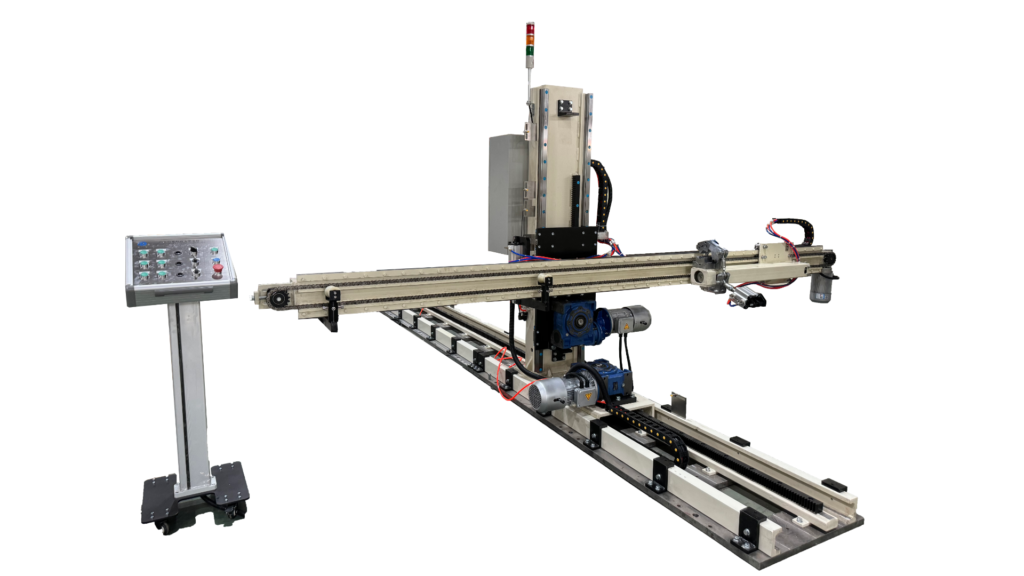

Fully automated pneumatic shaft extraction system designed to eliminate manual labor and protect expander shafts from damage.

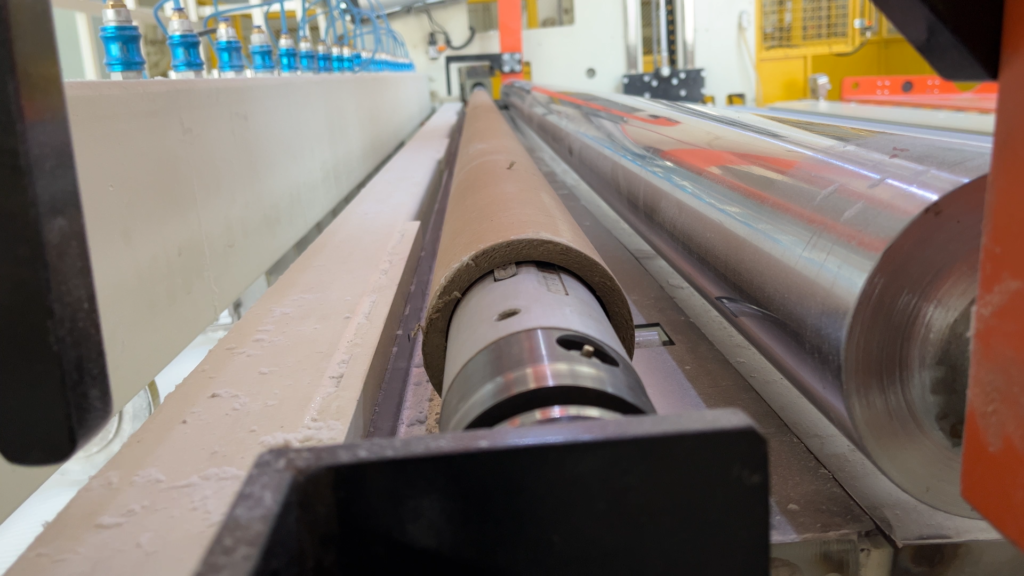

The ShaftMaster Auto-P transforms the most physically demanding task in the rewinding process into a simple, one-touch operation. Engineered with a mobile rail system and vertical height adjustment, it aligns perfectly with the rewinder core, grips the shaft pneumatically, and extracts it smoothly without bending or scratching the surface.

The motorized column adjusts vertical height with millimeter precision, ensuring the shaft is inserted or extracted exactly at the core’s center line, preventing damage to the cardboard journals.

Industrial-grade linear rails support the entire carriage travel. This rigid structure eliminates vibration and ensures smooth, consistent torque application during heavy shaft pulls.

The system operates within a dedicated safety cage with interlocked access doors. If the perimeter is breached during operation, the system halts instantly to protect personnel.

| Max. Shaft Length | Up to 3500mm (Customizable) |

| Max. Pulling Force | 500 kg |

| Pulling Speed | 15 - 30 m/min (Adjustable) |

| Lifting Stroke | 800mm - 1200mm |

| Drive System | AC Motor with Chain Transmission |

| Control System | PLC with Push-Button Interface |

| Total Power | 3.5 kW |

| Air Pressure | 6 Bar |

Get a Technical Proposal & Layout within 24h.