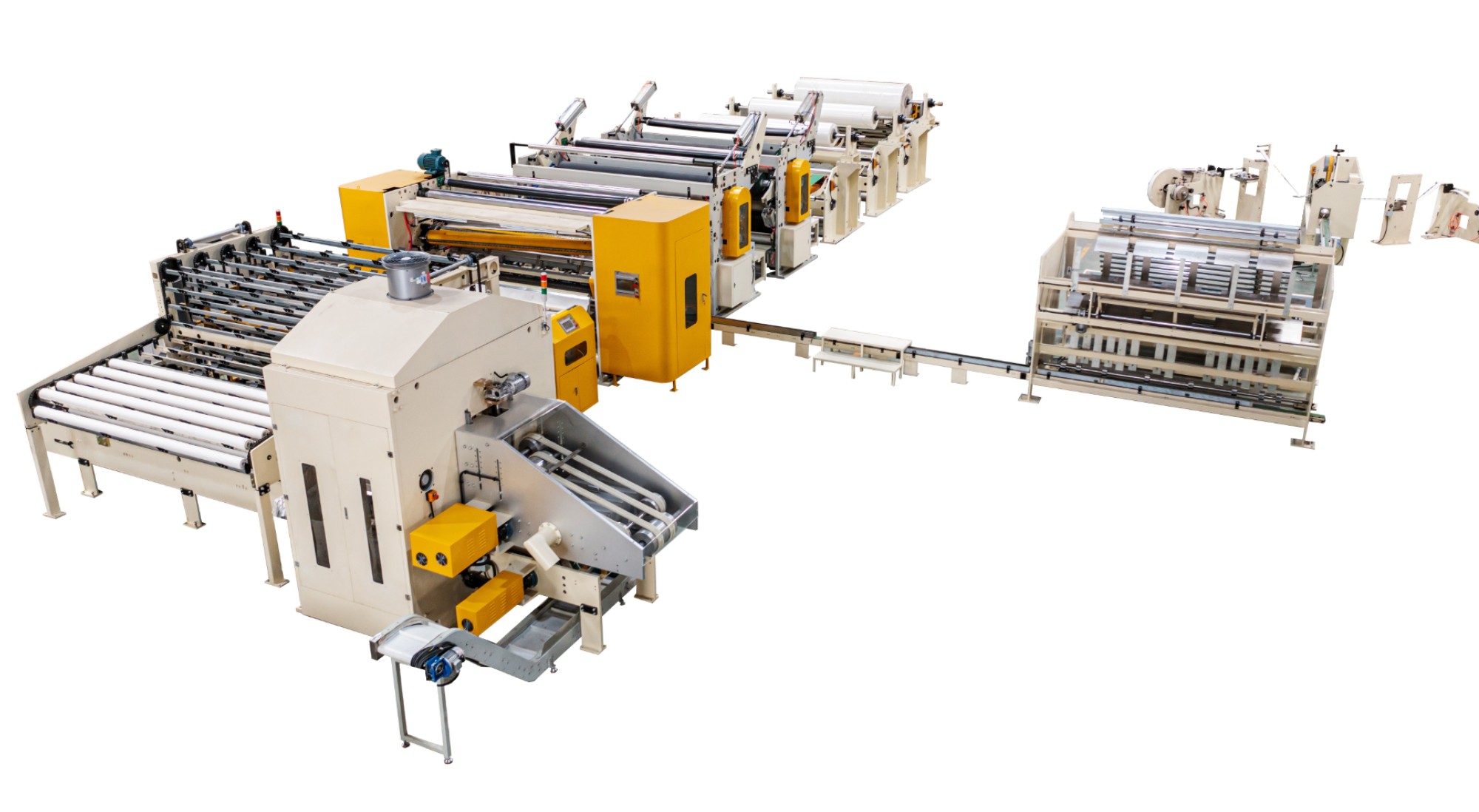

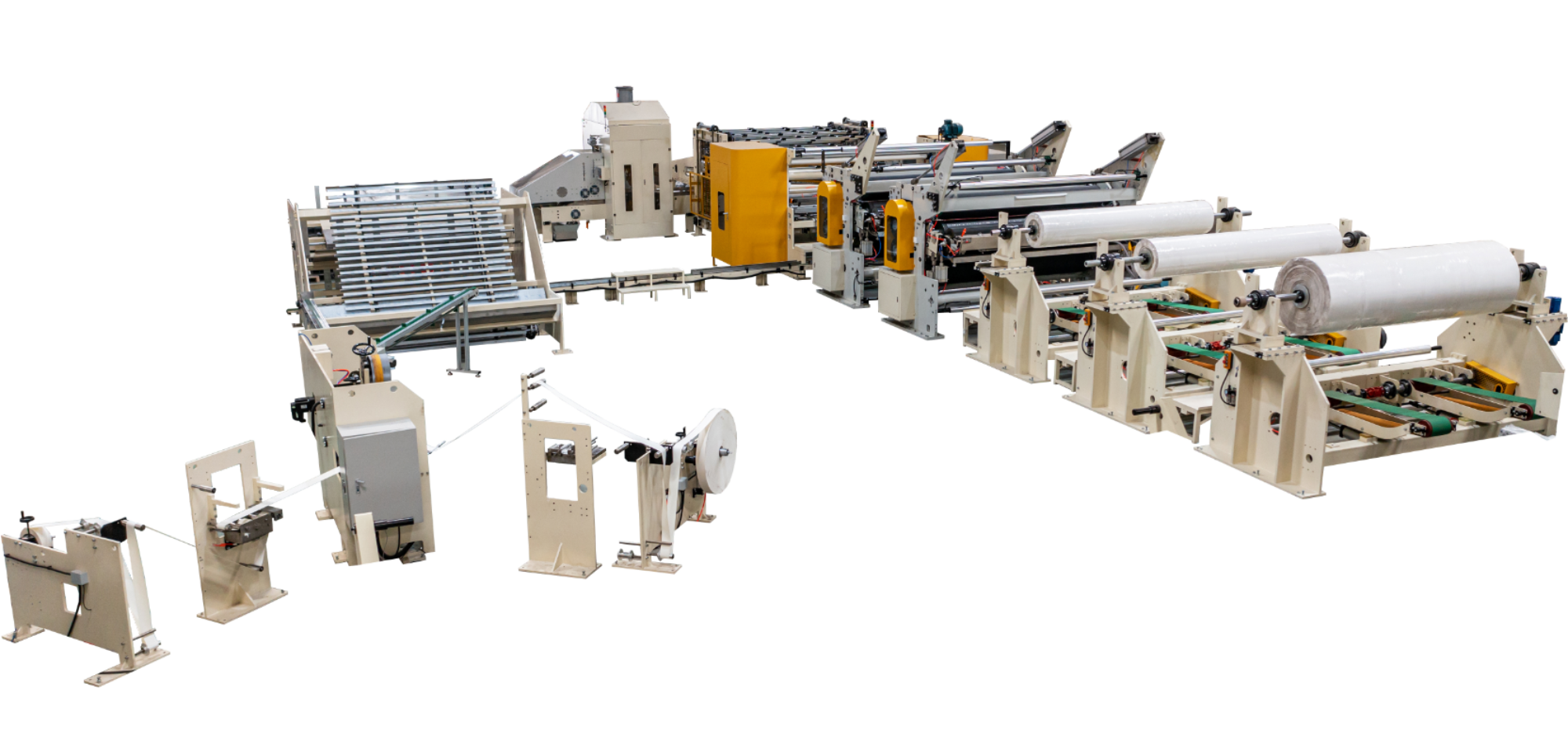

| Design Speed | 350 m/min |

| Production Speed | 300 m/min (Stable) |

| Working Width | 1750 mm - 3550 mm (Customizable) |

| Perforation System | 4-Piece Spiral Knife (High Durability) |

| Log Diameter | Φ70 - Φ135 mm |

| Rewinding Type | Non-Stop (Surface Winding) |

| Control System | PLC, Inverter, Optical-Electro-Mechanical Integration |

| Web Tension | Encoder, PLC, Inverter Feedback Loop |

| Coreless Speed | 250 m/min (Stable for Solid Rolls) |

| Technology | Patented Vacuum Suction System |

| Changeover | Convenient Core / Coreless Interchange |

| Finished Core Dia. | Φ38 - Φ50 mm (For Coreless) |

| Jumbo Core Size | Φ76.2 mm (Standard) |

| Backstand Capacity | 1 - 3 Ply (Independent Drive) |

| Embossing Unit | Steel to Rubber / Point-to-Point / Nested / DECO |

| Edge Embossing | Steel to Steel (Standard) |

| Printing Unit | 1 - 2 Colors (Optional Pattern) |

| Lamination | Glue Lamination System (Optional) |

Technical experts ready to respond within 24 business hours

Yes. The TB-R300 is designed as a Hybrid System. It features a “Convenient Interchange” design that allows operators to switch between standard cored rolls and solid coreless rolls efficiently, giving you maximum market versatility.

We follow a “Safety Oversizing” engineering philosophy. The machine is mechanically designed to handle 350 m/min, but we rate it at 300 m/min for continuous production. This ensures the components are never stressed to their limit, resulting in longer lifespan and vibration-free operation.

The TB-R300 is highly flexible. It supports standard Steel to Rubber embossing, but can also be upgraded to Point-to-Point, Nested, or DECO Embossing systems with lamination, allowing you to produce premium kitchen towels.

No special pit is required. The machine uses a flat installation layout. However, due to the Independent Motor Drive system, we recommend a standard reinforced concrete floor to ensure stability at high speeds.