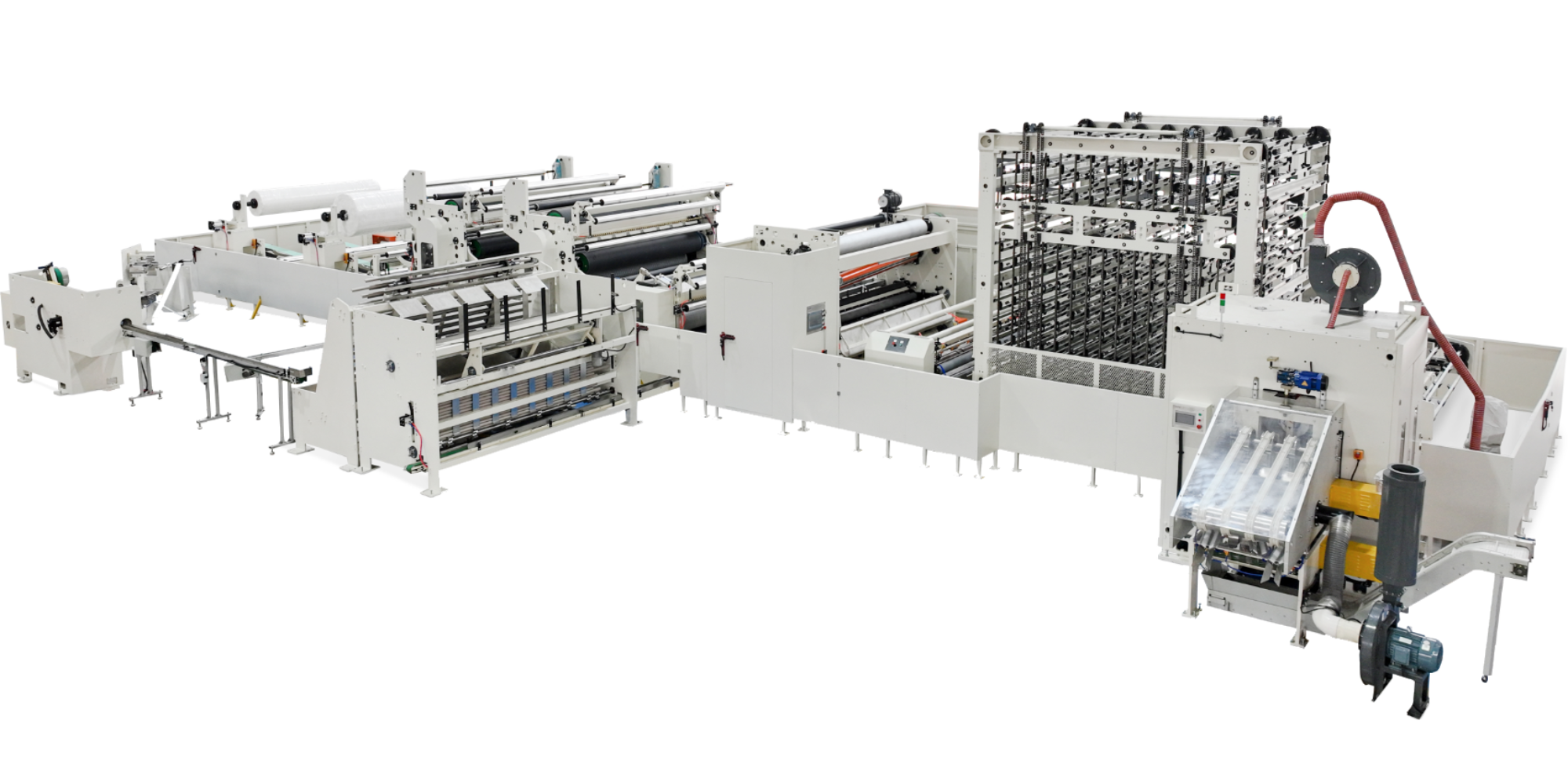

| Design Speed | 500 m/min |

| Production Speed | 450 - 500 m/min (Stable) |

| Log Output | 20 - 25 Logs/min |

| Jumbo Roll Width | 2850 mm (Customizable) |

| Jumbo Roll Diameter | ≤ Φ2500 - 3000 mm (Customizable) |

| Perforation System | Servo Control (Adjustable Pitch) |

| Control System | Siemens S7 PLC (Germany) |

| Motion Control | Siemens Servo Drives (Germany) |

| Electrical Parts | Schneider Electric (France) |

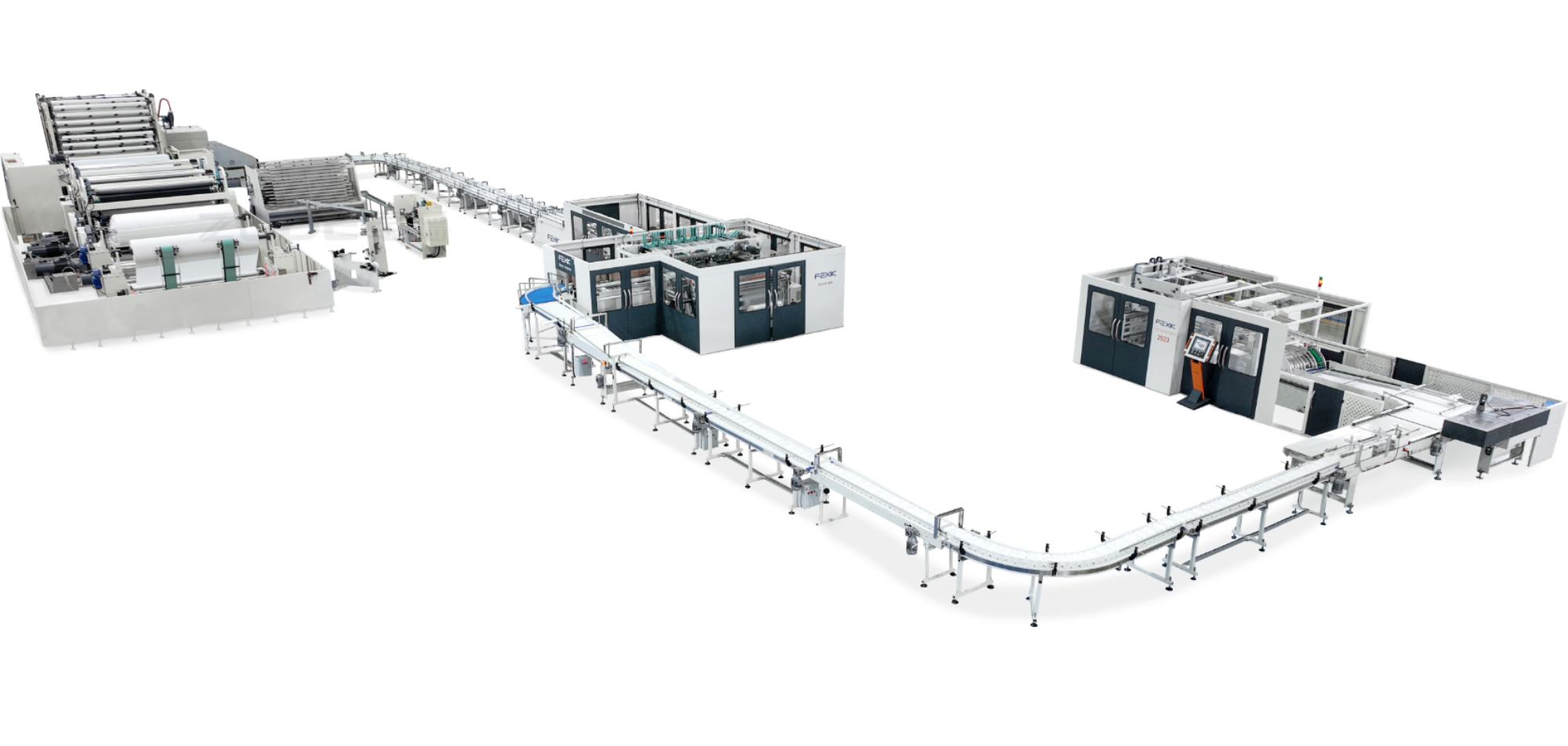

| Model Name | Orbit-Saw 200 (4-Channel System) |

| Design Speed | 200 Cuts/min |

| Production Speed | 150 - 180 Cuts/Min (Stable) |

| Feeding Channels | 4 Independent Channels |

| Cutting Tolerance | ±1 mm (Precision Grinding) |

| Dust Control | Integrated Suction System |

| Grinding System | Pneumatic Auto-Grinding |

| Backstand Capacity | 1 - 3 Ply (Independent Servo Drive) |

| Tension Control | Real-Time Monitoring System |

| Edge Embossing | Steel to Steel (Alloy Coated 70 HRC) |

| Lamination Unit | Point-to-Point / DES / Nested (Optional) |

| Bearing Type | High Precision Heavy-Duty Bearings |

| Web Cutting | Straight-in Machine Web Cutting |

Technical experts ready to respond within 24 business hours

Yes. The TB-R500 is specifically engineered for both Toilet Rolls and Kitchen Towels. It supports advanced Lamination Units (Point-to-Point or DES) and features a heavy-duty embossing unit with 70 HRC hardness, ensuring deep, crisp patterns even on multi-ply kitchen towel products.

Unlike traditional machines that use chains and gears, the TB-R500 series uses independent Siemens Servo Motors for each function unit. This results in higher precision, significantly less noise/vibration, reduced maintenance (no chains to grease), and faster format changes via the HMI.

The line is equipped with a Real-Time Tension Control System. Each unwind backstand has independent drives that monitor and adjust the web tension instantly, preventing paper breaks even when running at the maximum speed of 500 m/min.

Yes, thanks to the Servo Control Perforation system, you can adjust the perforation pitch (sheet length) directly from the touch screen (HMI) with extreme precision, ensuring consistent tear lines.