| Maximum Speed | 500 m/min |

| Alternation Speed | 25 logs/min |

| With Core Speed | 550 m/min |

| Jumbo Roll Width | 2850 mm (customizable) |

| Jumbo Roll Diameter | ≤ Φ2500 - 3000 mm (customizable) |

| Rewind Type | Non-Stop |

| Parameter Set | HMI |

| Control System | PLC, Inverter, Optical-Electro-Mechanical Integration |

| Tension Control | Encoder, PLC, Inverter |

| Backstand | 1 - 3 ply (independent drive) |

| Log Diameter | Φ60 - 130 MM |

| Tail Length | 5 - 30 mm (adjustable) |

| Speed | 25 Logs/Min |

| Power | 3kw |

| Design Speed | 200 Cuts/min |

| Drive System | Servo controlled feeding system |

| Production Speed | 180 Cuts/min (4 Rolls/cut) |

| Feeding Channel | 4 channels |

| Cutting Tolerance | ±1 mm |

| Log Size | Φ70 - 135 mm |

| Control System | PLC Integrated |

| Edge Embossing Unit | Steel To Steel |

Technical experts ready to respond within 24 business hours

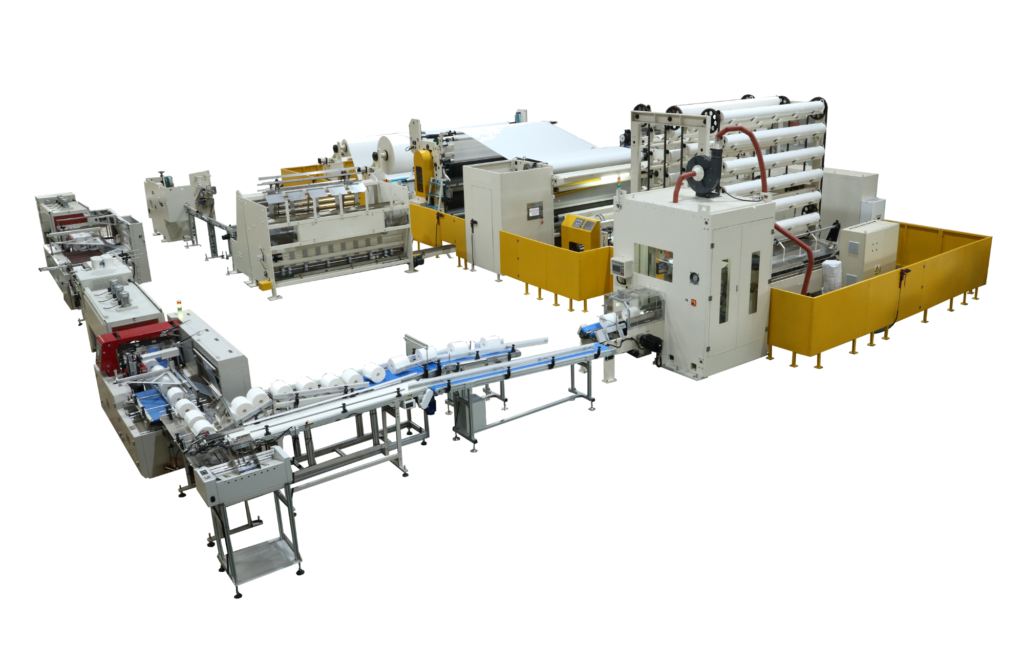

Yes. The TB-JRT500 is engineered for continuous 24/7 industrial performance, achieving a stable production speed of 500 m/min with an alternation rate of 25 logs/min. Unlike entry-level machines, our “Non-Stop” rewinding technology eliminates downtime during core changes, ensuring that your output remains consistent without sacrificing winding quality or perforation precision.

Absolutely. The system handles Jumbo Rolls with a standard width of 2850mm (customizable) and up to 3000mm in diameter. It is fully compatible with 1-3 ply configurations. The adjustable perforation pitch and tension control allow you to switch between high-density toilet paper and absorbent kitchen towels with minimal changeover time, maximizing your plant’s versatility.

We utilize a “High-Intelligence” architecture featuring a Siemens S7 PLC and advanced Motion Control. Independent servo drives (Encoder + Inverter) manage real-time tension at both the unwind and rewind stations. This prevents paper breakage at 500 m/min and guarantees perfectly uniform logs with a diameter range of Φ60–130mm, providing a premium finish that meets international retail standards.

We offer a turnkey solution for international clients. This includes on-site expert installation, commissioning, and intensive operator training. The TB-JRT500 comes with a comprehensive warranty (confirmar si es 12 meses/1 año) and a lifetime guarantee of spare parts availability. Our engineering team provides remote diagnostics to resolve any technical issues with zero latency.

Yes. We understand that every facility is different. The TB-JRT500 is modular; while the standard working width is 2850mm, we can adapt the backstand configuration and the overall footprint to fit your factory layout. We also customize power requirements (standard 380V, 50Hz, 3-Phase) to match your local electrical infrastructure.