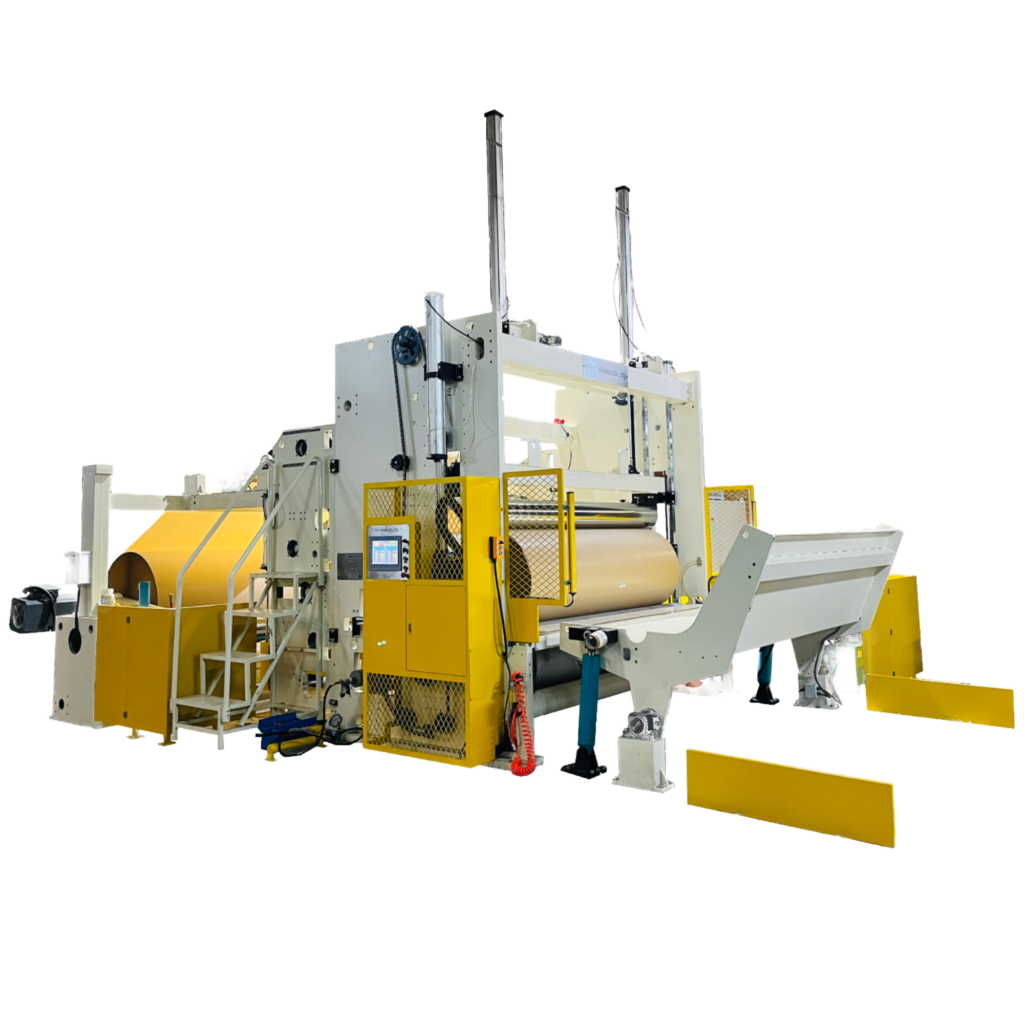

The benchmark for Kraft converting. Featuring laser core positioning and heavy-duty tension control for rapid changeovers at 1000 m/min

Minimizing downtime with smart automation and heavy-duty components for non-stop converting.

Siemens S7 PLC with closed-loop load cell feedback for constant web tension.

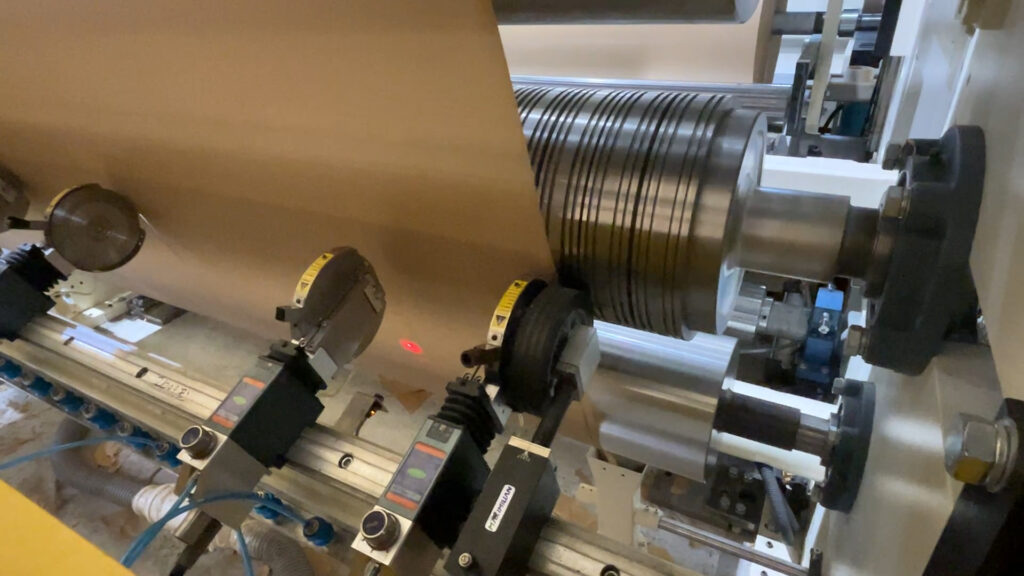

Flexible cutting modules adaptable to tissue grades and GSM requirements.

Optional automated knife setup for rapid format changes (< 2 mins).

Perfect density and structure for downstream converting efficiency.

Specialized high-speed processing for MG Paper & Wrapping materials.

| Machine Model | TB-MG1000 (MG Paper Series) |

| Application Material | MG Paper, Interleaving Paper, Wrapping Paper (14-120 gsm) |

| Working Speed | 1000 m/min |

| Working Width | 2850 mm / 3550 mm (Customizable) |

| Dia. of Finished Roll | ≤ Φ1200 mm |

| Dia. of Jumbo Roll | Φ 2000 mm / 2500 mm |

| Tension Control | Precise Closed-Loop Tension Control |

| Slitting System | Shear Knife / Razor Blade (Adjustable) |

| Rewinding System | Center-Surface Rewinding (For roll hardness control) |

| Control System | Siemens Motion Control System |

| Unwinder | Shaftless Unwind Stand (Hydraulic Lift) |

| Optional Units |

Auto-Splicing: Automatic paper splicing unit Trim Handling: Vacuum trim suction system Unloading: Automatic roll pusher |

Drastically reduce downtime. The integrated Laser Core Positioning System projects precise guidelines onto the rewinding shaft, allowing operators to align cores with knives instantly, ensuring perfect roll geometry from the first meter.

Engineered for the demands of heavy Kraft and Linerboard. The reinforced steel rollers and anti-wrinkle spreader system ensure smooth material flow at high speeds (1000 m/min), preventing web breaks even with 600+ gsm stock.

Production without compromise. The MG-1000 utilizes a decentralized drive system to maintain constant torque across the entire reel diameter (up to 1500mm), delivering rock-hard finished rolls ready for shipping.

Get a Technical Proposal & Layout within 24h.