The industry standard for reliability. Engineered for vibration-free stability and precision winding at 1200 m/min.

Minimizing downtime with smart automation and heavy-duty components for non-stop converting.

Reliable high-speed processing for volume production.

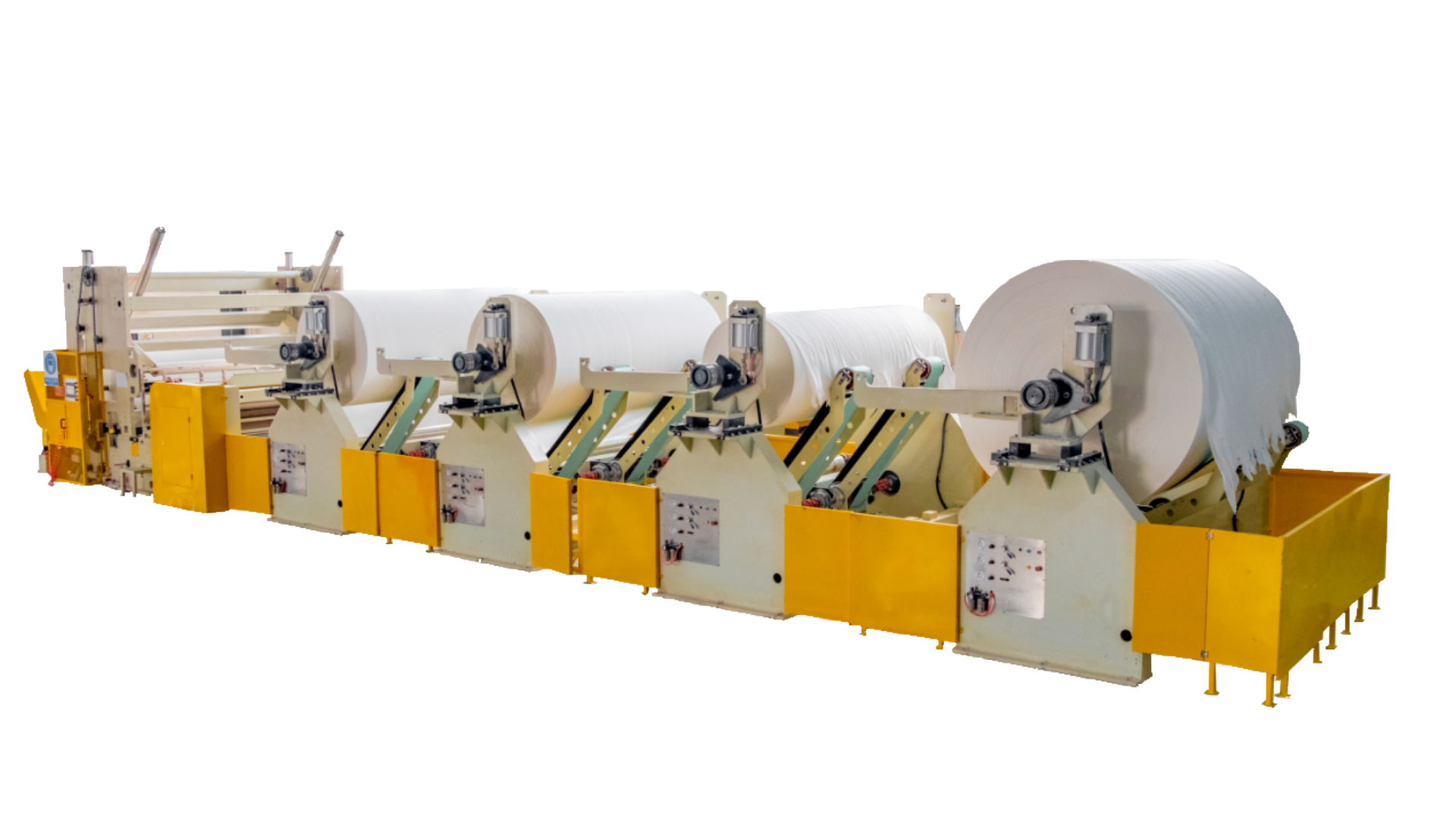

| Machine Model | TB-FQA1200 (FQ Series) |

| Working Speed | 1200 m/min |

| Width of Jumbo Roll | 2950 mm / 3550 mm / 3950 mm |

| Dia. of Finished Roll | ≤ Φ1500 mm (Standard) |

| Dia. of Jumbo Roll | Φ 2000 / 2500 / 3000 mm |

| Slitting Width | Min 80mm - Max to Jumbo roll width |

| Rewinding System | Pneumatic synchronous winding |

| Slitting System | Imported slitting knives (Shear/Razor) |

| Discharge System | Auto roll change + Hydraulic discharge |

| Control System | Siemens Motion Control System |

| Unwinder | 1-3 Backstands (Customizable) |

| Motive Power | Individual Inverter Control (~100KW) |

| Optional Units |

Calendering: Steel to Steel / Steel to Rubber Lamination: Point to point, decorative embossing Specialty: Double-side cream application |

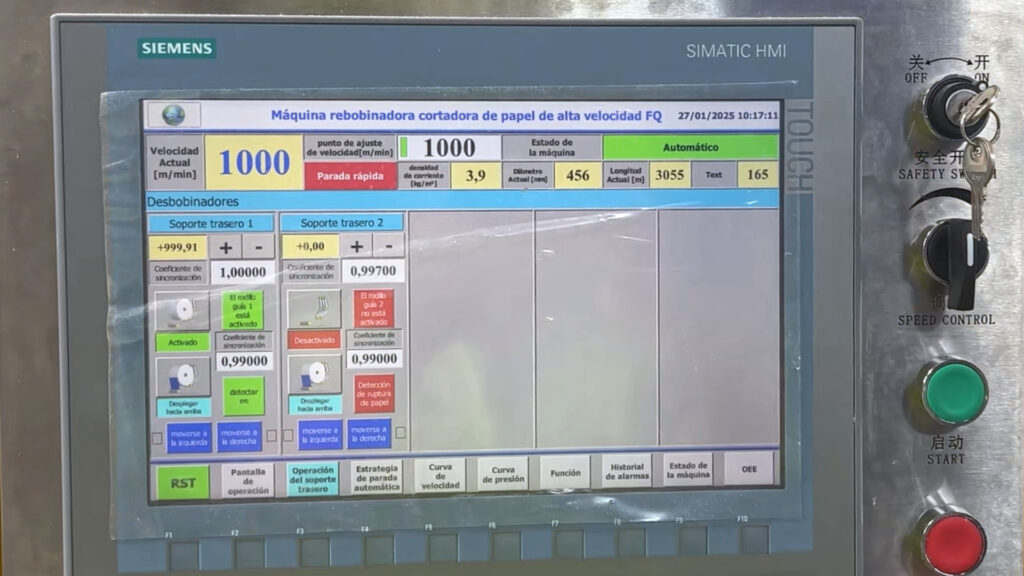

Features a native SIEMENS Simatic touch panel with real-time diagnostics. Operators can manage tension recipes, visualize speed curves (up to 1000+ m/min), and control individual servo drives with zero latency.

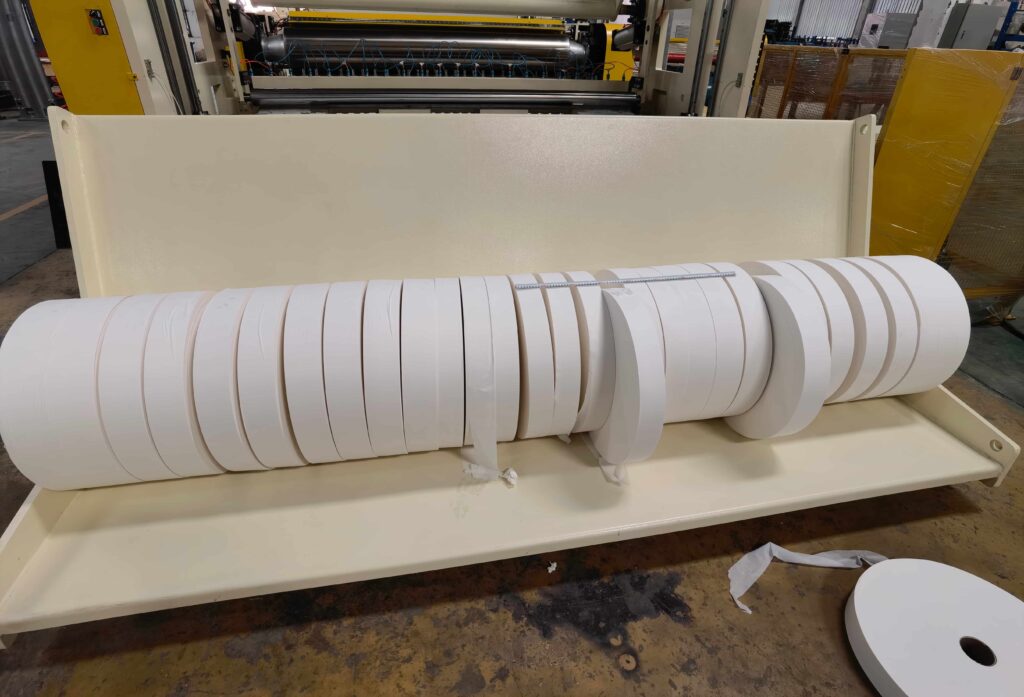

Features a heavy-duty knife assembly capable of minimum slit widths down to 50mm. The pneumatic locking system ensures rigid stability, eliminating blade vibration even when running maximum knife capacity.

The proof is in the winding. Our advanced spreader roll technology guarantees distinct roll separation, preventing interleaving even on narrow cuts. The hydraulic discharge table gently lowers heavy sets to floor level for safety.

Get a Technical Proposal & Layout within 24h.